When you need to remove large amounts of water from your reservoirs, but the lack of portability and electrical requirements of a conventional VAC Dehydration system hinders your efforts, Y2K has got you covered. Built with your needs in mind, we designed a unit that is portable and easy to get around while 110 Volts makes it easy to find power. Utilizing a standard filter cart frame, we made our unit easy to transport and move through doors, catwalks and most hard to reach areas a conventional dehydrator cannot fit. The portable vacuum dehydrator has the ability to filter oil viscosities up to 600cSt (ISO VG 680) at 100ºF within ambient temperature ranges of -15ºF to 180ºF. All Y2K products are 100% customizable upon request.

*Membrane system requires compressed air, Requirement of a minimum of 2.5 SCFM at 100 PSIG continuous duty.

Typical Applications:

- Hydraulic Reservoirs

- Pulp and Paper Lube Systems and Gearboxes

- Cooling Tower Gearboxes

- And Many Other Applications

Typical Industries:

- Power Generation

- Mining

- Pulp and Paper

- Steel

- Automotive Manufacturing

Portable Membrane Dehydration System

Portable Membrane Dehydration System

|

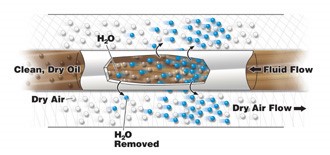

Membrane Dryer Technology:

Our advanced separation technology allows the water to pass directly from the oil into a dry air stream (or vacuum). This is achieved without any of the problems usually associated with conventional vacuum purifiers (foaming, flooding, viscosity changes, etc.). Oil flows through the dehydrator and over the patented structured packing which distributes the oil into relatively thin films with a large contact area. Dry compressed air is used to create a driving force for the mass transfer of the water to diffuse from the oil and into the air. The air with dissolved water vapor is then exhausted to atmosphere. |

|

|

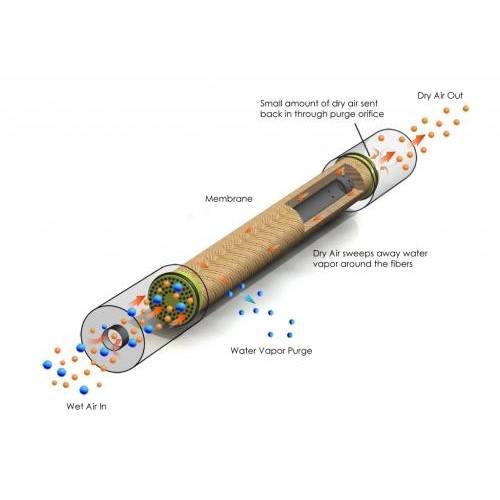

Air Dryer Technology:

Humid (compressed) air enters the membrane and its hollow fibers. A small amount of purged air is metered and directed to the outside of the fibers. Humidity is transferred through the fiber and is sent through the module to atmosphere as humid air. Dried air is sent out as low as -40 degrees or lower dew point. |

|

Typically, the degree of water removal will depend on the type of oil, it's affinity for water (water solubility), and the rate of water ingression into the system.